I spent most of the day replacing a shock absorber on my truck. It took me from 9 to 6 to replace one shock absorber. One shock absorber!

I quickly learned there’s a lot of rust on suspension parts which ‘welds’ them together. Suspension parts are also in awkward places. Finally, it took two trips to the auto parts store to get the right shocks.

I felt like, and acted like, the new guy today. I made every mistake in the book and wouldn’t be surprised if I came up with some new ones.

The only way to learn how to replace shocks is by doing it. It’s not the same as reading the repair manual or watching a YouTube video. I was bound to make mistakes, mistakes I had to make to learn, mistakes I’ll never make again.

In life there are mistakes you have to make. Whether it’s your first time changing shocks, your first bank account, your first relationship. There are mistakes we all have to make to learn and move forward.

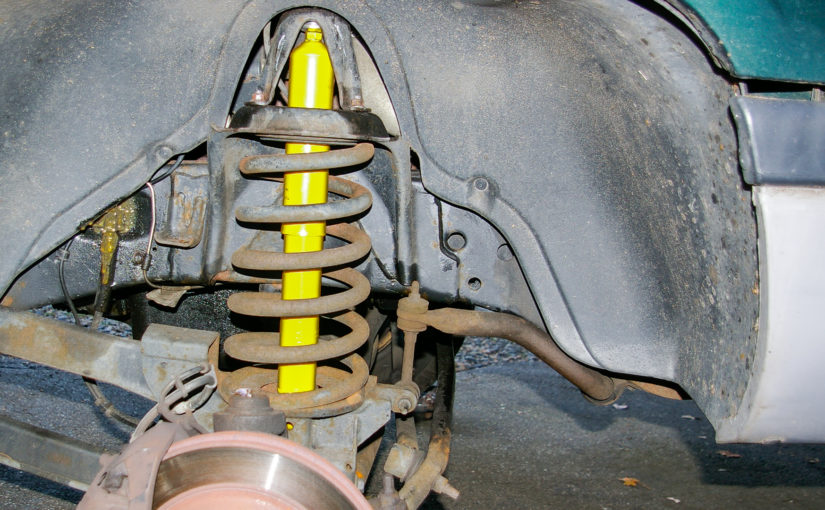

If you’re replacing shocks in a 2002 Dodge Ram 2500 (1) use an impact wrench to remove the top bolt; (2) take off the tire before you try to loosen the bottom bolt and (3) if you need to replace a nut on the shock tower they’re metric M10-1.5 not standard 3/8-16.

Lessons learned!

Comments

6 responses to “Some Mistakes We Have to Make”

John in my experience the first one always takes all day. The second one then only takes an hour. I’ve been fooling about with our quad bike for days now. It wouldn’t start. Fuel was OK and it had spark.

As the spark looked quite good I assumed it was a fuel fault. I pulled the carburetor out and gave it a clean [watched Donnyboy 73 video 😉 ]. This sounds simple but I had to do a couple of hours work removing cowlings and the handle bars etc to access the carb [looking at Donny’s video they improved the cowling on later models to make it easier to remove]. While I was at it and it was accessible I cleaned out the fuel tank. Neither seemed that bad. Result of all this work? The bike still wouldn’t start. After a bit of fiddling about I changed the spark plug as I was told that it could be breaking down under load. Replacing the plug brought the bike back to life however while a mile away from the shed it died yet again. The way it died seemed like an intermittent ignition fault. Off came the bars and cowling again [this time it didn’t take me as long as the first time as I knew what I was doing] so I could get at the coil. The coil tested OK but I thought I might replace it anyway. That was until I found out that a new one would cost $300 for a new one. So I cleaned up all the connections on the coil and reassembled it. The bike ran again for a couple of days before stopping yet again. Now I was getting rather frustrated by all this and was going to throw in the towel and send it out for service. I decided that before I did this I would change the oil and check the filter [this bike is 30 years old and has done a lot of work. It is the Yamaha you see in my videos]. It is difficult to explain but the whole family use this bike so I don’t know when the oil was last changed but the oil was very tried and the filter partially blocked. I suspect with the oil filter partially blocked when the oil thinned out [as it heated up] the oil pressure dropped to a point where it stopped the engine. As unlikely as this sounds the bike [touch wood] has run OK this week. Next week might bring something new but I am running out of options if it stops again. All good fun isn’t it!

Hows the fire wood pile looking heading into winter? Built any Holden Housens. 😉

Rod I feel your pain. I’m glad to hear I’m not the only one who goes through all that when repairing items. I try to justify the time as keeping my mind sharp. I haven’t done much wood splitting this year. It’s nice to be almost caught up for a while.

Well so long as you get a “A” in your shock absorber class life should be easier the next time around…..

It looks so easy on TV. Lesson learned.

Ive been working on my truck a lot i use to get down a lot because it would take so long and make mistakes but now i know its going to take time and i enjoy the process we can do anything

It took me a long time to learn that lesson. The shock absorber still amazed me with how long it took but I know I’ll never make the same mistake(s) again. Like you, I enjoy the process and figuring stuff out. The key is to have plenty of time, or a backup vehicle, when working on the car.